Henry Avocado

Henry Avocado

Escondido, California

Description

Henry Avocado has been growing and packaging avocados since 1925. C&L Refrigeration was chosen to help design and build the refrigeration system for their new Escondido plant. After reviewing many initial designs and energy analysis, C&L designed and constructed an industrial multi-compressor rack system for the new avocado packaging and distribution plant. The refrigeration system services Forced Air (FA) ripening rooms capable of operating from 40°F to 70°F room temperatures for custom-ripening of avocados, coolers, palletizing area, and docks. The project included semi-hermetic screw compressors with backup capacity, evaporative cooling, and a total of thirty-two evaporator fan coils. A separate independent refrigeration system was also designed and constructed for the bin cooler where avocados are brought in after harvest. The new Escondido plant allows Henry Avocado to custom ripen more than 1.5 million cartons of avocados annually with room to expand.

Quick Facts

- Design/build industrial multi-compressor refrigeration rack system for avocado plant

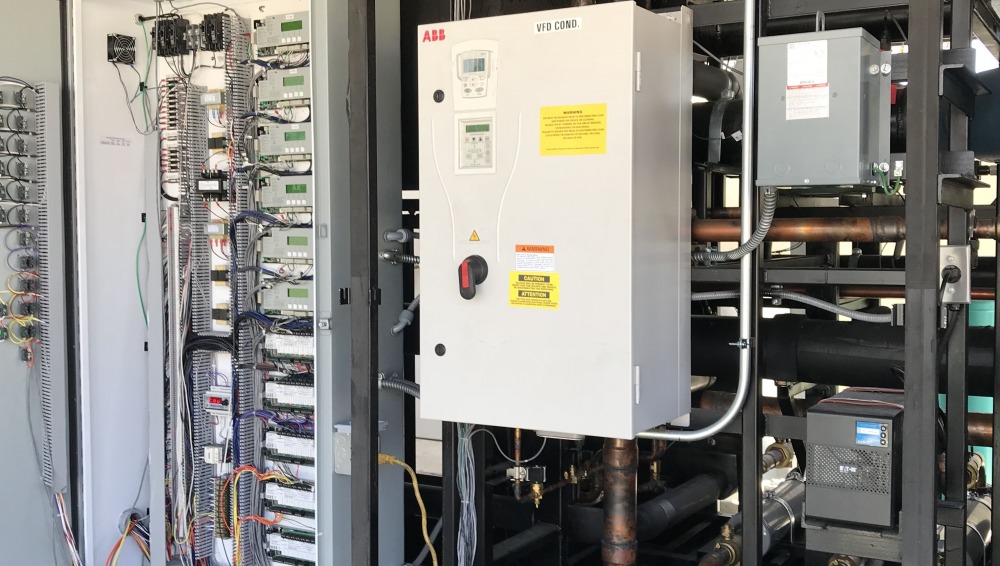

- Controls integrated with remote monitoring and trending capabilities

- Bin Cooler cooling 85°F entering products in 12 hours

- Allow custom ripening of more than 1.5 million cartons of avocados annually and room to expand